FABRIC QUALITY INSPECTION

The Fabric Quality Module is an integral component of the quality control system, designed to ensure that every fabric roll produced meets the highest standards of quality and reliability. In this module, we employ cutting-edge technology, including tablets, and a user-friendly software interface that empowers our quality inspectors to identify and address fabric faults efficiently.

Key Components of the Fabric Quality Module:

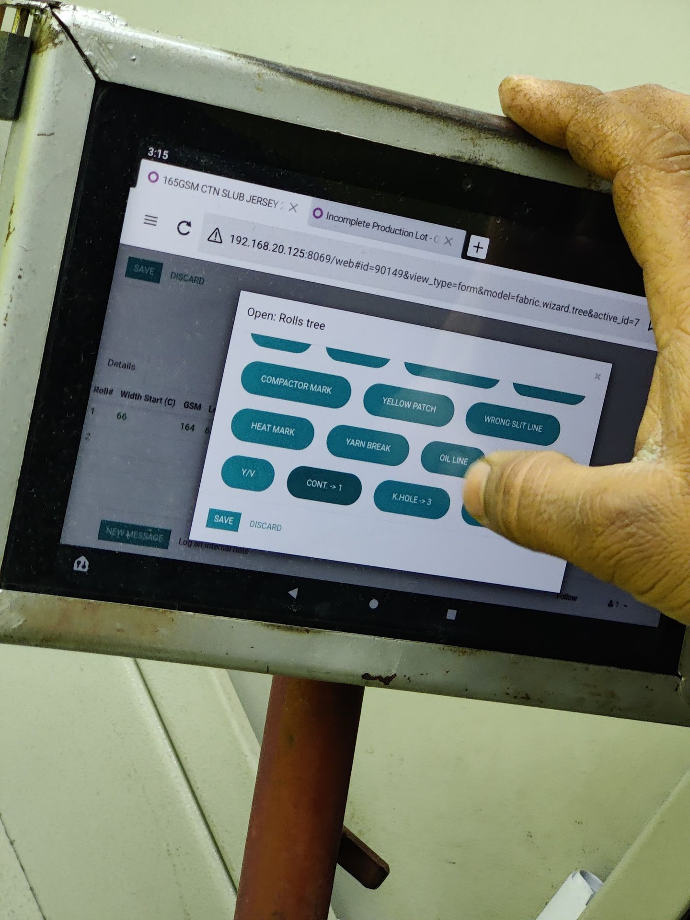

Use of Tablets:

The quality inspectors utilize tablets to access the Fabric Quality Module. The biggest challenge for us was to provide a user-friendly interface so that fabric inspectors with no prior computer literacy can easily understand, learn and work on it. Thanks to our dedicated and hardworking team of developers, we developed and designed the right solution.

Now the Quality inspectors can easily search and select the fabric in software of which they are doing inspection and can easily enter faults as per their findings.

Fault Identification:

Quality inspectors are presented with a comprehensive list of fabric fault options within the software. These faults can range from colour discrepancies and weaving irregularities to material defects and pattern inconsistencies (i.e. Dust mark, Slit line, Needle Line, Compactor marks etc.)

Fault Selection:

For each fabric roll under inspection, quality inspectors can select fault types by simply clicking on the corresponding buttons within the software. This intuitive interface minimizes the margin for error and streamlines the inspection process.

Supervisor Review:

Once the quality inspector has identified and selected fault types, they send the inspection results to their supervisor for further assessment. The supervisor plays a crucial role in ensuring the accuracy and consistency of the quality assessment.

Fabric Shrinkage Entry:

In addition to fault identification, supervisors also enter the fabric shrinkage level for each fabric roll. This data is vital for understanding the fabric's behaviour under various conditions and maintaining consistent quality standards as per required results.

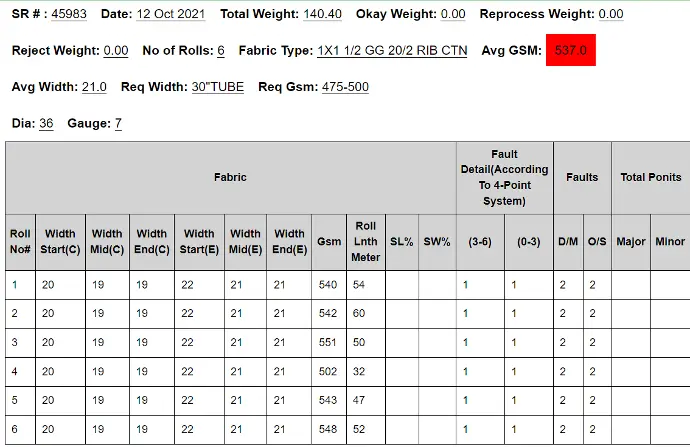

Quality Report Generation:

Based on the fault types entered by quality inspectors, a detailed quality report is automatically generated for each fabric roll. This report provides a comprehensive overview of the fabric's condition, highlighting any areas that require attention or improvement.

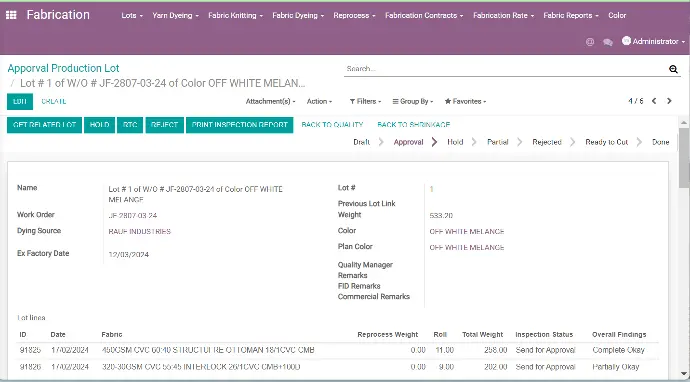

Quality Manager Approval:

After the supervisor's review and the entry of fabric shrinkage levels, the data is forwarded to the quality manager for final approval. The quality manager plays a pivotal role in ensuring that the fabric meets the company's quality benchmarks.

Quality Manager Choice of Decisions:

After reviewing the Quality Inspection report, if fabric meets the required standards then the quality manager provides his approval, and if fabric is not as per standards then quality manager has the option to provide his remarks and send it back to either Quality re-check, Send for reprocess or Reject the fabric.

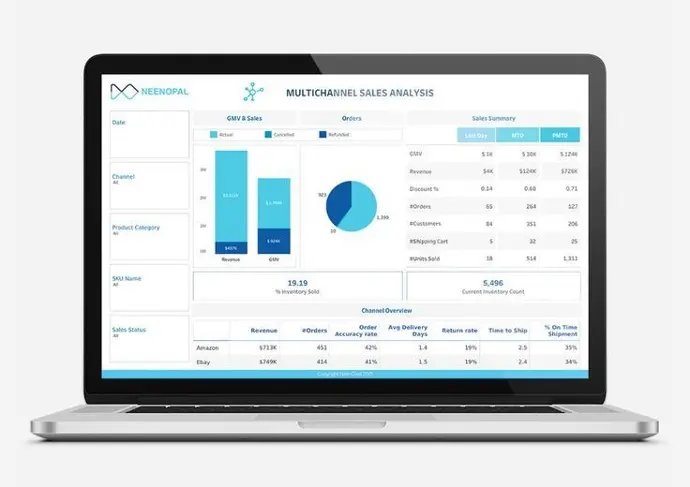

Data Analytics and Feedback Loop:

The Fabric Quality Module doesn't just end with reporting. It forms part of a continuous improvement cycle, where data from inspections and reports are analysed to identify trends, quality issues, and areas for optimization. This feedback loop helps our clients to enhance their manufacturing processes over time.

Benefits of Using Our Quality Inspection Module

Enhanced Efficiency:

The Fabric Quality Module streamlines the inspection process, allowing inspectors to easily search, select, and enter faults, minimizing time and effort required for quality assessment.

Improved Accuracy:

With a comprehensive list of fabric fault options and an intuitive interface for fault selection, the module ensures precise identification and recording of fabric defects, reducing the margin for error.

Supervisor Oversight:

The module facilitates supervisor review, ensuring an additional layer of quality control to maintain accuracy and consistency in the inspection process.

Better Quality Management:

By recording fabric shrinkage levels and generating detailed quality reports, the module enables proactive management of fabric quality, facilitating timely interventions and improvements.

Streamlined Approval Process:

The module automates the approval process by forwarding inspection results to the quality manager, expediting decision-making and ensuring adherence to quality benchmarks.

Continuous Improvement:

Through data analytics and feedback loops, the module facilitates continuous improvement by identifying trends, quality issues, and areas for optimization, empowering clients to enhance their manufacturing processes over time.

In conclusion, our Fabric Quality Module leverages technology to enhance the fabric inspection process, making it more efficient, accurate, and transparent. It empowers our clients to uphold the highest quality standards in their fabric production, ultimately delivering superior products to their customers.