Garment Stitching Module

Numlatex recognizes the pivotal role of garment stitching in the textile manufacturing process. Our Garment Stitching Module is intricately crafted to enhance and streamline stitching operations for textile enterprises. With a keen emphasis on efficiency, precision, and transparency, our module provides a holistic solution tailored to the distinctive requirements of garment stitching processes.

Key features

Work Order Management:

Easily create, assign, and track work orders for garment stitching operations, ensuring clarity and accountability throughout the process.

Operator Efficiency Tracking:

Monitor operator efficiency and performance metrics, including time taken per operation, number of pieces stitched, and overall productivity.

Stitching Line Efficiency:

Analyze the efficiency of each stitching line, identify bottlenecks, and optimize workflow for maximum throughput and resource utilization.

Real-time Visibility:

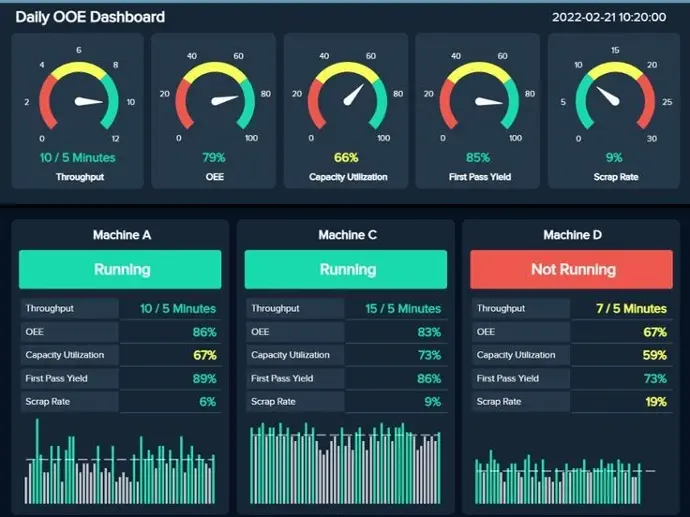

Gain real-time visibility into work order status, operator performance, and stitching line efficiency, empowering managers to make informed decisions and take proactive actions.

Efficiency Comparison:

Compare efficiency metrics between different stitching lines to identify best practices, areas for improvement, and opportunities for optimization.

.

Reporting & Analyses:

- Work Order Status:

View the status of each work order in real-time, including progress, completion status, and any pending tasks. - Operator Efficiency:

Track the efficiency of each operator, including time taken per operation, number of pieces stitched, and overall productivity. - Stitching Line Efficiency:

Analyze the efficiency of each stitching line, compare performance metrics, and identify areas for improvement. - Efficiency Comparison:

Compare efficiency metrics between different stitching lines to identify best practices and optimize resource allocation. - Operation Time Analysis:

View detailed reports on the time required for each operation, identify bottlenecks, and streamline workflow for improved efficiency

.

Benefits of Using Our Garment Stitching Module

Enhanced Efficiency:

Our Garment Stitching Module streamlines and automates manual processes, reducing lead times and increasing throughput for garment stitching operations.

Improved Productivity:

By tracking operator efficiency and stitching line performance, our module helps identify opportunities for process improvement and resource optimization, leading to increased productivity.

Transparency and Accountability:

With real-time visibility into work order status and operator performance, managers can hold operators accountable for their work and ensure adherence to production schedules.

.

Data-driven Decision Making:

Access detailed reports and analytics on operator efficiency, stitching line performance, and overall productivity, enabling data-driven decision-making and continuous improvement initiatives.

Cost Savings:

Optimize resource utilization and minimize waste with efficient fabric dyeing processes, leading to cost savings and improved profitability.

Customer Satisfaction:

Deliver on-time and high-quality fabric products that meet or exceed customer expectations, enhancing customer satisfaction and loyalty.

With our Garment Stitching Module, textile businesses can streamline stitching operations, improve productivity, and achieve operational excellence in garment manufacturing. Experience seamless garment stitching management with Numlatex, your trusted ERP solution provider in the textile sector.